Keli Motor Group Search

Internet of Things

Summary:With the rise of the Internet of things (IOT), big data and AI technology, factory equipment has ushered in a brand new revolution.

With the rise of the Internet of things (IOT), big data and AI technology, factory equipment has ushered in a brand new revolution. More and more machines are connected to the Internet to realize remote data monitoring and analysis, which brings workers easier and more efficient work. However, many people are unfamiliar with this model, and blindly following the trend may not get the desired effect, so how can enterprises combine the IOT, big data, and enhance the value of the factory?

At present, the biggest application of the IOT in the industrial field is predictive maintenance. It was difficult to ensure the continuous operation of the production line 24 hours a day for a long time in the past, but today predictive maintenance can solve the hidden trouble of equipment in advance, so as to prevent equipment failure and shutdown.

Motor is the main force of the industry today, the factory has a lot of motors for various purposes, such as lifting, stamping, handling, dust removal, drying and other equipment to use the motor. The maintenance of the motor has become an important issue in the factory, especially in some harsh environments, users prefer to remote maintenance.

Motor efficiency degradation is the most common. If hundreds of motors in the factory are reduced in efficiency, the impact on production is great, and there is also the risk of downtime. In some production lines, the failure of one motor can cause an entire production line to shut down, which can be very expensive.

In order to reduce unexpected downtime, the plant employs maintenance personnel. But traditional maintenance methods are also expensive because they don't have a better way to predict the future of the equipment and still can't avoid downtime. Usually the motor has the following maintenance methods

Maintenance after failure: it means that the maintenance will be carried out after the motor breaks down. In this case, the motor is usually damaged and a new motor needs to be replaced, because it is not a simple matter to repair the motor on site. In this case, it can only be replaced first to ensure that the production can continue.

Preventive maintenance: in order to avoid complete failure of the motor, the staff will perform regular maintenance based on the average running time of the motor.Often, Usually for safety reasons, maintenance happens accidentally too early, but parts are still in good condition and may be replaced, which does not guarantee that new problems will not occur after maintenance

Condition monitoring and maintenance: Usually, there will be some phenomena before the motor shuts down, such as noise, vibration, and uneven speed. The method of condition monitoring and maintenance is to monitor each motor, similar to the doctor's stethoscope. and maintenance personnel determine whether maintenance is needed after on-site diagnosis. Field testing can be a dangerous task, with maintenance personnel have to run anywhere in the factory

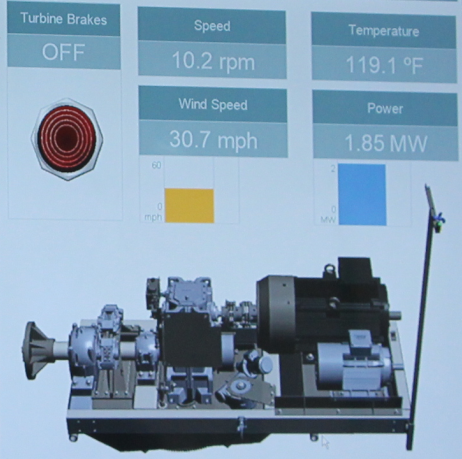

With the development of Internet of things technology, these traditional maintenance methods will become a thing of the past. Each motor will be equipped with one or more sensors that are connected to a control database to continuously collect data about the motor. In the database, AI is used to learn the behavior of each motor and generate an alarm immediately when the motor deviates from the normal situation

This sensor-based data collection is more accurate and thorough than any human detection, because many signs of the motor are hard to recognize with the eyes and ears, but the Internet of things sensors can detect small changes in the device.

The combination of the Internet of Things and artificial intelligence can not only see problems, but also continuously scan and detect possible problems. This method is called predictive maintenance. This is a great way to avoid breakdown and let the maintainer know when the best time to maintain is not too slow or too early. At the same time, depending on the severity of the problem and alarm, you can even plan the downtime of the motor to minimize interference with the operation

In the operation of the factory, wrong decisions or decisions made too slowly and too early will bring a lot of waste of resources and money. The Internet of things helps users collect data they've never captured before, analyze it with AI, learn from it and make better decisions faster.